| Tool Description | Minimum Dia. (mm)

DMIN | Cutting Length

(mm)

LU | Clearance (mm)

CDX | Radius (mm)

RE | Gauge Length

(mm)

OHX | WF

(mm) | Shank Dia.

(mm)

DCON |

| MGBR.1706054 ET82P | 1.7 | 6.0 | 0.2 | 0.05 | 13 | 0.70 | 4 |

Type: Unimaster MGB Miniature Tool

Application: Designed to machine boring and profiling small bores.

Grade: ET82P - First choice for general grooving. PVD multi-layer coating, suitable for most materials TiN.

Excellent for: Steels, Stainless Steels, Cast Iron and Heat Resistant Super Alloys.

How to set up the tool in your machine

The tool is inserted into the corresponding holder (where the tool shank and holder bore match). The tool is then orientated to the correct angle by the holder internal pin against the angle on the shank end and is finally clamped by the holder screw on the tool's flatted shank.

Coolant can be supplied via the rear diameter of the holder, along its length and is accurately delivered from 2 slots either side of the cutting tool. Please see images in the above description for further illustration.

Miniature Holder Coating

All Europa turning, grooving and threading holders now have E-COAT eco-friendly coating to give up to five times longer tool life.

- High abrasion resistance

- High surface hardness >60HRc

- High resistance to tempering

- High fatigue strength

- High scratch & impact resistance

- High corrosion resistance

- Up to 5 times longer tool life

- E-COAT is environmentally friendly

- Coating has no impact on human health

- Non-polluting process used in coating tools

Feed Rate & Depth of Cut

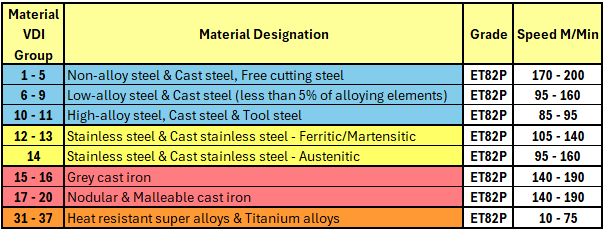

Speeds Chart

Use our "Material Search Engine" link below to quickly find, confirm and provide more detailed information on the classification and designation of the material you are working with: