| Thread

Dia.

D1 | Pitch | Thread Form | Thread

Length

L2 | Overall

Length

OAL | Shank

Dia

D2 | Square

Sq | Tapping

Drill

Dia. |

| M3 | 0.5mm | Metric Coarse | 11mm | 56mm | 3.5mm | 2.7mm | 2.8mm |

Flute Type: Thread Forming/Fluteless

Recommended for: Forming Threads in materials with at least 10% elongation

Shank Standard: DIN 371

Type: High speed steel Cobalt (HSSE)

Coating: TiAlN (Titanium Aluminium Nitride) - This is a special coating for machining abrasive materials such as Grey cast iron, Al-alloys with silicon, fibre reinforced plastics, etc., or machining under high temperatures, such as insufficient coolant or high speeds> 600m/min. TiAlN coating has a hardness of approx. 3,000 HV and is temperature resistant up to approx. 800°C.

Colour: Violet Grey Coefficient of friction against steel: 0.4

Tapping Materials

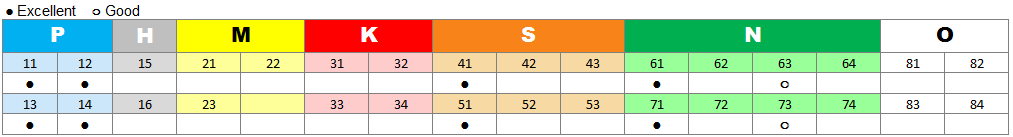

Excellent for tapping: All General Steels; Unalloyed Titanium; Unalloyed Nickel; Unalloyed Copper; and Unalloyed Aluminium

Good for tapping: Long Chipping Copper Alloys; and Aluminium with Silicone content 0.5-10%