| Thread

Dia.

D1 | Pitch | Thread Form | Thread

Length

L2 | Overall

Length

OAL | Shank

Dia

D2 | Square

Sq | Tapping

Drill

Dia. |

| M2 | 0.4mm | Metric Coarse | 8mm | 45mm | 2.8mm | 2.1mm | 1.6mm |

Flute Type: Spiral Point

Recommended for: Through Holes

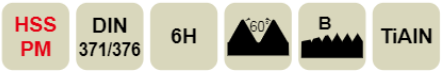

Shank Standard: DIN 371

Type: High speed steel Powder Metallurgy (HSS PM)

Coating: TiAlN (Titanium Aluminium Nitride) - This is a special coating for machining abrasive materials such as Grey cast iron, Al-alloys with silicon, fibre reinforced plastics, etc., or machining under high temperatures, such as insufficient coolant or high speeds> 600m/min. TiAlN coating has a hardness of approx. 3,000 HV and is temperature resistant up to approx. 800°C.

Colour: Violet Grey Coefficient of friction against steel: 0.4

Tapping Materials

Excellent for tapping: Alloy/Tempered Steels; Hardened Steels; and Nickel Alloys

Good for tapping: Titanium Alloys